I had some issues with the code on the Pic Processor and I would like to post that information for the sake of someone else who might want more background on a design close to this one.

Here is the link: https://forum.microchip.com/s/topic/a5CV40000002DZ3MAM/t398142

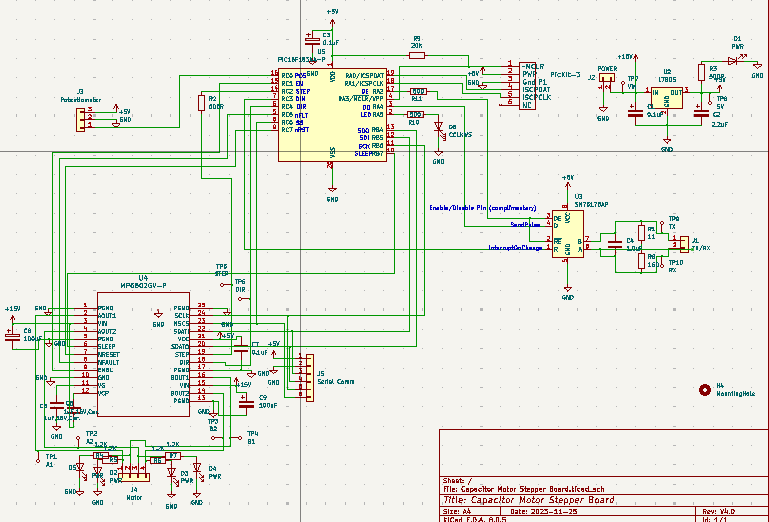

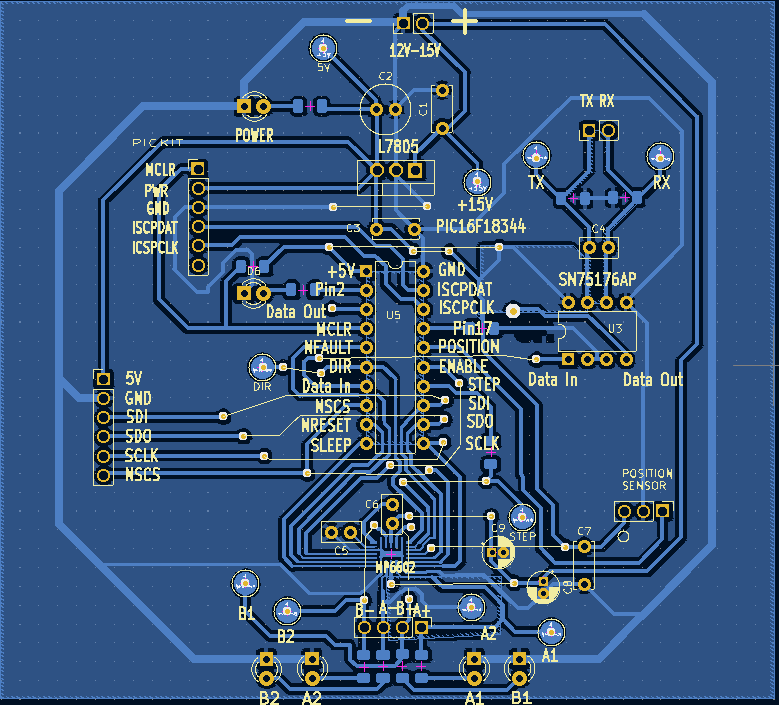

The software I used was used to operate another and simpler motor, but not a stepper. I added the Stepper Motor Code to it, most of it with MP6022 names for the routines. I include the main.c file here simply so you can see what I am attempting or how I am testing the MP6022. The important part is setup and operation of the MP6022. I did not write this code for you to look at, so ask me if you have questions about what part I think it doing what with; it is probably difficult to follow without some study. I think writing a “1” to the Ctrl.step bit should make the motor advance.

At the first occurrence of “for(int i = 0; i < 200; i++) {” is where I have the motor setup as in the application node and am sending STEP commands - expecting the motor to operate.

Here is main.c

/*

- File: main.c

- Author: tmiller

*/

#include <xc.h>

#include <stdio.h>

#include <stdlib.h>

#include <math.h>

#include “user.h”

#include “system.h”

#include “MP6602.h”

volatile unsigned int pulseCount;

volatile unsigned int Timer0Int;

char lastStep;

unsigned int nFault = 0;

extern unsigned int SPIRead, ReadSDI;

unsigned int MP6602RegisterValues[8];

int main(int argc, char** argv) {

static unsigned char Answer1, Answer2;

unsigned long int i;

int avgIntPerRev; // Calibrated value of interrupts in Capacitance range.

int totalintLimit;

double tuning;

double oldtuning;

int numberOfSteps;

int oldNumberOfSteps;

unsigned char direction;

unsigned int oldPulseCount;

unsigned int stepCount;

unsigned int savPulseCount;

unsigned int firstPulseCount = 0;

char buf[10], sbuf[5];

unsigned int OffTimeChanged = 0;

unsigned int StepModeChanged = 0;

unsigned int EnableChanged = 0;

unsigned int BlankingTimeChanged = 0;

unsigned int SteppingCurrentLimitChanged = 0;

unsigned int StepIndexChanged = 0;

unsigned int Faultschanged = 0;

unsigned int STEPChanged = 0;

PMD0bits.NVMMD = 1; // Disable NVM Module

PMD1bits.NCOMD = 1; // Disable NCO

PMD1bits.TMR6MD = 1; // Disable TMR6

PMD1bits.TMR5MD = 1; // Disable TMR5

PMD1bits.TMR4MD = 1; // Disable TMR4

PMD1bits.TMR3MD = 1; // Disable TMR3

PMD2bits.DACMD = 1; // Disable DAC

PMD3bits.CWG1MD = 1; // Disable CWG

PMD3bits.CWG2MD = 1; // Disable CWG

PMD3bits.PWM6MD = 1; // Disable PWM

PMD3bits.CCP4MD = 1; // Disable Capture and Compare

PMD3bits.CCP3MD = 1;

PMD3bits.CCP2MD = 1;

PMD3bits.CCP1MD = 1;

PMD4bits.UART1MD = 1; // Disable UART1

PMD4bits.MSSP2MD = 1; // Disable MSSP

PMD5bits.CLC1MD = 1; // Disable Configure Logic Cell

PMD5bits.CLC2MD = 1; // Disable CLC2

PMD5bits.CLC3MD = 1; // Disable CLC3

PMD5bits.CLC4MD = 1; // Disable CLC4

PMD5bits.DSMMD = 1; // Disable DSM

// MP6602 FAULT Pin Configuration

// The nFAULT pin reports fault conditions and

// is driven low when a fault condition occurs.

// If the fault condition is released, the nFAULT

// pin is pulled high by an external pull up resistor.

// So long as the pin is high there is no fault condition 1=NoFault

// It reflects the bit setting in the FAULT register

LATCbits.LATC5 = 0; // Clear the Latch of the FAULT pin

ANSELCbits.ANSC5 = 0; // Digital port

ODCONCbits.ODCC5 = 1; // Open Drain (Sink Current Only) Disabled

TRISCbits.TRISC5 = 1; // Fault pin of MP6022

WPUCbits.WPUC5 = 1; // The MP6602 nFault Pin is pulled high by this resistor

// Port Control

// 18345 Output LED

ANSELAbits.ANSA5 = 0; // Digital pin

INLVLAbits.INLVLA5 = 0; // TTL Input Level for Input / Its an Output Pin

LATAbits.LATA5 = 0; // Nothing out yet

ODCONAbits.ODCA5 = 0; // Open Drain on (Sink Current Only) OFF/ its output

SLRCONAbits.SLRA5 = 1; // Slew Rate Control on - to make it easier on the processor

TRISAbits.TRISA5 = 0; // Port is Output

WPUAbits.WPUA5 = 0; // Weak Pull Up Resistor not used.

LATAbits.LATA5 = 1;

// Enable Pin MP6602

ANSELCbits.ANSC1= 0; // Digital Pin

INLVLCbits.INLVLC1 =0; //TTL Input -its an output

ODCONCbits.ODCC1 = 1; // Not Open Drain (Sinks and Sources current)

SLRCONCbits.SLRC1 = 1; // Slew Rate Control On

TRISCbits.TRISC1 = 0; // Output to enable/disable (Pin,not register)

WPUCbits.WPUC1 = 0; // No pull up (i is internal pull down)

LATCbits.LATC1 = 0; // MP6602 Not Enabled through this pin

// Step Pin MP6602

ANSELCbits.ANSC2 = 0; // Digital Pin

INLVLCbits.INLVLC2 =0; //TTL Input -its an output

ODCONCbits.ODCC2 = 1; // Not Open Drain (Sinks and Sources current)

SLRCONCbits.SLRC2 = 1; // Slew Rate Control On

TRISCbits.TRISC2 = 0; // Output to STEP (Pin,not register)

WPUCbits.WPUC2 = 0; // No pull up (i is internal pull down)

LATCbits.LATC2 = 0; // MP6602 Not Enabled through this pin

// DIR (direction) Pin MP6602

ANSELCbits.ANSC4= 0; // Digital Pin

INLVLCbits.INLVLC4 =0; //TTL Input -its an output

ODCONCbits.ODCC4 = 1; // Not Open Drain (Sinks and Sources current)

SLRCONCbits.SLRC4 = 1; // Slew Rate Control On

TRISCbits.TRISC4 = 0; // Output to DIR (Pin,not register)

WPUCbits.WPUC4 = 0; // No pull up (i is internal pull down)

LATCbits.LATC4 = 0; // MP6602 Not Enabled through this pin

INTCONbits.GIE = 1; // Enable all interrupts that are enabled.

INTCONbits.PEIE = 1;

CLKRCONbits.CLKREN = 0; // Reference clock disabled.

#ifdef USE_IOC

PIE1 = 1; // Enable timer 2 interrupt

INTCONbits.GIE = 1; // Enable all interrupts that are enabled.

INTCONbits.INTE = 0;

// Stepper Motor Setup

RB6PPS = 0b11000; // RC6 port at pin 11 is assigned as SCK1

SSP1CLKPPS = 0b01110; // SCLK1 is at RB6

RB5PPS = 0b11001; // RB5 port at pin 12 is assigned as SDO1

SSP1DATPPS = 0b1100; // Peripheral SSP1SDI is at RB4

SSP1SSPPS = 0b10110; // SS1 is at RC6 pin 8

LATBbits.LATB4 = LATBbits.LATB5 = LATBbits.LATB6 = LATCbits.LATC6 = 0;

ANSELBbits.ANSB4 = ANSELBbits.ANSB5 = ANSELBbits.ANSB6 = ANSELCbits.ANSC6 = 0; // Digital pins

WPUBbits.WPUB4 = WPUBbits.WPUB5 = WPUBbits.WPUB6 = WPUCbits.WPUC6 = 1; // Weak Pull ups

ODCONBbits.ODCB4 = 1; // Open drain (sink current only)

SLRCONBbits.SLRB4 = 1; // Slew Rate enabled (slows it down)

INLVLBbits.INLVLB4 = 1; // ST input (lower voltage for high)

TRISBbits.TRISB4 = 1; // SDI (TRIS=1) RB4/13

TRISBbits.TRISB5 = 0; // SDO (TRIS=0) RB5/12

TRISBbits.TRISB6 = 0; // SCLK (TRIS=0) RB6/11

TRISCbits.TRISC6 = 0; // ~SS (TRIS=1) RC6/8

// SP1BRG = 0x13; // 400kHz

// SPI Interrupts

PIR1bits.SSP1IF = 0; // Clear Read/Write Status interrupt Flag

PIR1bits.BCL1IF = 0; // Clear Bit Collision on SPI1 interrupt Flag

PIE1bits.SSP1IE = 1; // Read or write complete on SPI1

PIE1bits.BCL1IE = 1; // Bit Collision on SPI1

// PMD4bits.MSSP1MD = 0; // Enable MSSP module to set ports

SSP1ADD = 0x13; // 400kHz

SSP1CON1bits.SSPM = 0b1010; // SPI Master Mode, clock = FOSC/4 = 32MHz/64 = 500kHz

SSP1CON1bits.CKP = 1; // Clock idle (Clock Polarity) state is high so MP6620 Data shifts on the rising edge of SCLK

SSP1STATbits.CKE = 0; // Transmit occurs on transition from active to idle clock state.

SSP1STATbits.SMP = 0; // Input data sampled at end of data output time.

SSP1CON1bits.SSPEN = 1; // ENable SPI

LATCbits.LATC7 = 0;

LATCbits.LATC1 = 0;

LATBbits.LATB7 = 0;

LATCbits.LATC2 = 0;

LATCbits.LATC4 = 0;

ANSELCbits.ANSC7 = 0; // Reset Pin digital

ANSELCbits.ANSC1 = 0; // Enable Pin digital

ANSELBbits.ANSB7 = 0; // Sleep Pin digital

ANSELCbits.ANSC2 = 0; // STEP Pin digital

ANSELCbits.ANSC4 = 0; // DIR Pin digital

TRISCbits.TRISC7 = 0; // Reset Pin output

TRISCbits.TRISC1 = 0; // Enable Pin output

TRISBbits.TRISB7 = 0; // Sleep Pin Output

TRISCbits.TRISC2 = 0; // STEP pin Output

TRISCbits.TRISC4 = 0; // DIR Pin Output

// Leave enable pin dis-enabled (C1)

// Leave out of sleep (B7)

// Leave STEP not stepping (C2)

// Leave DIR the same (low/C4)

// Reset MP6602 - drive pin 7 reset low

WPUCbits.WPUC7 = 1; // Enable weak pull up on Reset Pin

LATCbits.LATC7 = 1; // Pull up Reset to end RESET (C7)

LATBbits.LATB7 = 0; // Sleep mode inactive

LATCbits.LATC1 = 0; // Enable through register, not pin

__delay_ms(1);

static unsigned int CtrlValue;

static unsigned int RegisterValue;

//

// First one does not work well.

CtrlValue = ReadMP6602(0x00);

FAULTRegValue = ReadMP6602(0x0E); // Read the Fault register because VCCUV is holding the device in RESET mode

FillFAULTRegStruct(FAULTRegValue); // Fill in the structure

FAULTReg.VCCUV = 1; // Write a 1 to VCCUV to clear Reset mode

FAULTRegValue = MakeFAULTRegDataInteger(); // Make the integer to write to the FAULT register

WriteMP6602(0x0E,FAULTRegValue); // Write to the FAULT Register

FAULTRegValue = ReadMP6602(0x0E); // Read it back to verify

// Read All The Initial Register Values

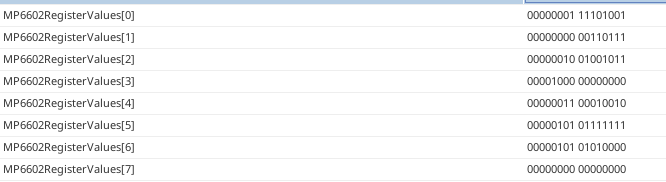

CtrlRegValue = MP6602RegisterValues[0] = ReadMP6602(0x00);

Ctrl2RegValue = MP6602RegisterValues[1] = ReadMP6602(0x02);

ISETRegValue = MP6602RegisterValues[2] = ReadMP6602(0x04);

StallRegValue = MP6602RegisterValues[3] = ReadMP6602(0x06);

BEMFRegValue = MP6602RegisterValues[4] = ReadMP6602(0x08);

TSTPRegValue = MP6602RegisterValues[5] = ReadMP6602(0x0A);

OCPRegValue = MP6602RegisterValues[6] = ReadMP6602(0x0C);

FAULTRegValue = MP6602RegisterValues[7] = ReadMP6602(0x0E);

// Read Control Register 1 and fill in the CtrlReg Structure

// It includes the hold time, the off time, the step mode/increment,

// the direction, step, and enable commands.

ISETRegValue = ReadMP6602(0x04); // Read the ISET Register

FillISETRegStruct(ISETRegValue); // Fill in the stored Structure copy

ISETReg.PeakCurrentStepping.IS = 0x0b; // Set Step Current at 1.5 Amperes

ISETRegValue = MakeISETRegDataInteger(); // Make the new Data Value word.

WriteMP6602(0x04,ISETRegValue); // Configure the MP6602

ISETRegValue = ReadMP6602(0x04); // Read the ISET Register to confirm

CtrlRegValue = ReadMP6602(0x00); // Read Ctrl Register to change off time

FillCtrlRegStruct(CtrlRegValue); // Fill in processor memory copy

CtrlReg.OffTime.OT = 0b111; // Modify (fixed) Off Time (between steps)

CtrlRegValue = MakeCtrlRegDataInteger(); // Make the register transmit value

WriteMP6602(0x00,CtrlRegValue); // Write to the Motor Controller (MP6602)

CtrlRegValue = ReadMP6602(0x00); // Read back Ctrl to confirm

Ctrl2RegValue = ReadMP6602(0x02); // Read Ctrl2 Register to change blanking time

FillCtrlRegStruct(Ctrl2RegValue);

Ctrl2Reg.BlankingTime.BT = 0b111;

Ctrl2RegValue = MakeCtrl2RegDataInteger();

WriteMP6602(0x02,Ctrl2RegValue);

Ctrl2RegValue = ReadMP6602(0x02); // Read Back Ctrl2 to verify

CtrlRegValue = ReadMP6602(0x00); // Read Ctrl Register to change Step Mode

FillCtrlRegStruct(CtrlRegValue);

CtrlReg.StepModeTime.MS = 0b101;

CtrlRegValue = MakeCtrlRegDataInteger();

WriteMP6602(0x00,CtrlRegValue);

CtrlRegValue = ReadMP6602(0x00); // Read Ctrl Register to verify

TSTPRegValue = ReadMP6602(0x0A); // Read TSTP Register to start step counter at 0

FillCtrlRegStruct(TSTPRegValue);

TSTPReg.StepIndex.STP = 0;

TSTPRegValue = MakeTSTPRegDataInteger();

WriteMP6602(0x0A,TSTPRegValue);

TSTPRegValue = ReadMP6602(0x0A); // Read TSTP Register to verify

CtrlRegValue = ReadMP6602(0x00); // Read Ctrl Register to set enable bit

FillCtrlRegStruct(CtrlRegValue);

CtrlReg.EN = 1;

CtrlRegValue = MakeCtrlRegDataInteger();

WriteMP6602(0x00,CtrlRegValue);

CtrlRegValue = ReadMP6602(0x00); // Read Ctrl Register to set enable bit

FillCtrlRegStruct(CtrlRegValue);

CtrlReg.STEP = 1;

CtrlRegValue = MakeCtrlRegDataInteger();

unsigned int changed = checkRegisterValues(CtrlRegValue,Ctrl2RegValue,ISETRegValue,StallRegValue,BEMFRegValue,TSTPRegValue,OCPRegValue,FAULTRegValue);

if(changed & 0b10000000)

if (!((CtrlRegValue&0b000000000010) & 0b000000000010))

NOP(); // Step Changed

if(changed & 0b00010000)

NOP(); // Stall changed

if(changed & 0b00001000)

NOP(); // BEMF changed

for(int i = 0; i < 200; i++) {

WriteMP6602(0x00,CtrlRegValue);

CtrlRegValue = ReadMP6602(0x00); // Read Ctrl Register to set enable bit

FillCtrlRegStruct(CtrlRegValue);

TSTPRegValue = ReadMP6602(0x0A);

CtrlReg.STEP = 1;

CtrlRegValue = MakeCtrlRegDataInteger();

TSTPRegValue = ReadMP6602(0x0A); // Read TSTP Register to start step counter at 0

FillCtrlRegStruct(TSTPRegValue);

__delay_ms(1000);

}

TSTPRegValue = ReadMP6602(0x0A);

FillTSTPRegStruct(TSTPRegValue);

for (int i = 0; i< 200; i++) {

TSTPReg.StepIndex.STP = 0;

TSTPRegValue = MakeCtrlRegDataInteger();

WriteMP6602(0x0A,TSTPRegValue);

TSTPReg.StepIndex.STP = 0x20;

TSTPRegValue = MakeCtrlRegDataInteger();

WriteMP6602(0x0A,TSTPRegValue);

}

changed = checkRegisterValues(CtrlRegValue,Ctrl2RegValue,ISETRegValue,StallRegValue,BEMFRegValue,TSTPRegValue,OCPRegValue,FAULTRegValue);

if(changed & 0b10000000)

if (!((CtrlRegValue&0b000000000010) & 0b000000000010))

NOP(); // Step Changed

if(changed & 0b00010000)

NOP(); // Stall changed

if(changed & 0b00001000)

NOP(); // BEMF changed

for(int i = 0; i < 10; i++) {

PORTCbits.RC2 = 1; // Step

}

// Change the stored copy

// while(1) {

// Alter the memory copy of the first Control register to step

// CtrlReg.STEP = 1;

// Make the data integer to write to the MP6602

// CtrlRegValue = MakeCtrlRegDataInteger(); // Fill in the bitwise Ctrl Register Value

// Write the new contents with the step bit set (should step the motor)

// CtrlValue = WriteMP6602(0x00,CtrlRegValue); // Write the new value

// Read ALL the Registers and fill in the associcated structures.

while(!(OffTimeChanged || StepModeChanged || EnableChanged ||

BlankingTimeChanged || SteppingCurrentLimitChanged ||

StepIndexChanged || Faultschanged)) {

CtrlRegValue = ReadMP6602(0x00);

FillCtrlRegStruct(CtrlRegValue);

if(CtrlReg.OffTime.OT != 0b111)

OffTimeChanged = 1;

if(CtrlReg.StepModeTime.MS != 5)

StepModeChanged = 1;

if(CtrlReg.EN != 1)

EnableChanged = 1;

Ctrl2RegValue = ReadMP6602(0x02);

FillCtrl2RegStruct(Ctrl2RegValue);

if(Ctrl2Reg.BlankingTime.BT != 0b111)

BlankingTimeChanged = 1;

ISETRegValue = ReadMP6602(0x04);

FillISETRegStruct(ISETRegValue);

if(ISETReg.PeakCurrentStepping.IS != 0x0B)

SteppingCurrentLimitChanged = 1;

StallRegValue = ReadMP6602(0x06);

FillStallRegStruct(StallRegValue);

BEMFRegValue = ReadMP6602(0x08);

FillBEMFRegStruct(BEMFRegValue);

TSTPRegValue = ReadMP6602(0x0A);

FillTSTPRegStruct(TSTPRegValue);

if(TSTPReg.StepIndex.STP != 0)

StepIndexChanged = 1;

OCPRegValue = ReadMP6602(0x0C);

FillOCPRegStruct(OCPRegValue);

FAULTRegValue = ReadMP6602(0x0E);

FillFAULTRegStruct(FAULTRegValue);

if(FAULTRegValue != 0)

Faultschanged = 1;

__delay_ms(2000);

};

// // Record the change to the 1st Control Structure (so I can see what changed)

// FillCtrlRegStruct(CtrlRegValue);

// // Read the Step Table register to see if it increments

// TSTPRegValue = ReadMP6602(0x0A); // Read the Step Register

// // Record the state of the step table to the memory structure

// FillTSTPRegStruct(TSTPRegValue); // fill in the most recent data.

// }

CtrlRegValue = ReadMP6602(0x00); // Read the new value from the MP6602

CtrlRegValue = MakeCtrlRegDataInteger();

while(1) {

// CtrlValue = WriteMP6602(0x0,CtrlValue);

NOP();

// CtrlRegValue = ReadMP6602(0x00);

}

CtrlValue = WriteMP6602(0x0,CtrlRegValue);

CtrlRegValue = ReadMP6602(0x00);

CtrlValue = WriteMP6602(0x0,CtrlRegValue);

CtrlRegValue = ReadMP6602(0x00);

CtrlValue = WriteMP6602(0x0,CtrlRegValue);

// ISETReg.ISETRegValue = ReadMP6022(0x40);

// StallReg.StallRegValue = ReadMP6022(0x60);

// BEMFReg.BEMFRegValue = ReadMP6022(0x80);

// TSTPReg.TSTPRegValue = ReadMP6022(0xA0);

// OCPReg.OCPRegValue = ReadMP6022(0xC0);

// FAULTReg.FAULTRegValue = ReadMP6022(0xE0);

SPIRead = 0; // Do not read on interrupt

LATCbits.LATC6 = 1; // Slave not selected

RegisterValue = ReadMP6602(0x0);

RegisterValue = RegisterValue ^ 0x038; // Exclusive or will zero all these bits out

RegisterValue = RegisterValue | 0x028; // Set the step size in 3 bits (1/32)

RegisterValue = WriteMP6602(0x0, RegisterValue); // 1/32 step size

RegisterValue = WriteMP6602(0x0,0x100); // Off Time (default 40us)

RegisterValue = WriteMP6602(0x2,0x004); // Blanking time (default 2us)

RegisterValue = WriteMP6602(0x4,0x280); // Hold Mode steeping 1.5A

RegisterValue = WriteMP6602(0x0,0x200); // Time until Automatic Hold Time stops (15.6ms)